The olive harvesting began on October 5, 2021 at 10:30 a.m.

Enjoy your Arbequina Oil

Learn about the entire process of our oil from...

Everything starts in the field

FROM THE FIELD TO THE OIL MILL

The olives arrived at the Mill on the same day at 12:37 p.m.

PROCESSES

To make our oil, 7 steps are necessary

1. WASHING

We separate the olive from the leaves and remove the soil.

2. WAITING HOPPER

The waiting time in the hopper is minimal. Our goal is to keep it as short as possible to avoid oxidation of the olives.

3. GROUND AND BLENDED

These processes are necessary to homogenize the resulting paste. This phase lasts approximately 1 and a half hours.

4. CENTRIFUGING

First in the vertical centrifuge to separate solid and liquid. Then horizontally to separate the different liquids, that is, the vegetable water from the oil.

5. DECANTING AND FILTERING

The objective is to eliminate water or residues that have not been separated in previous processes and thus prevent the evolution of EVOO and maintain all its properties.

6. DEPOSITS

The product is stored in 30,000 liter tanks at a controlled temperature.

7. PACKAGING

Moment in which the bottles are filled with EVOO to obtain the final product as a result.

What do we do with the waste produced?

Click to find out

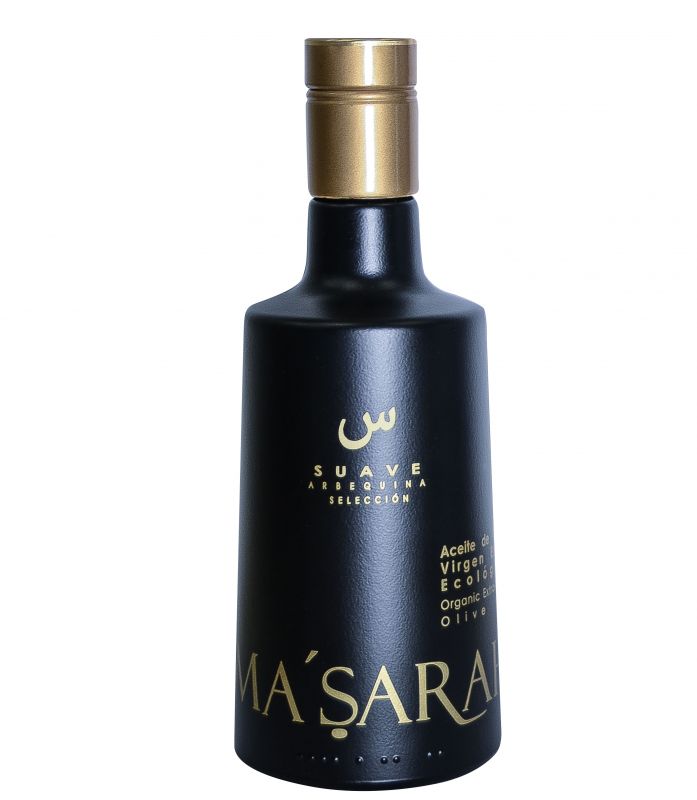

FINAL PRODUCT

Once packaged we obtain the final product, a Monovarietal Organic EVOO of superior quality.

Fruity oil, reminiscent of green tomatoes, with an aroma of freshly cut grass, artichokes and green almonds. On the palate it presents an elegant and smooth entry. Its flavor is intense and slightly saline, with an aromatic touch of parsley and basil. With a sweet almond finish.

Do you want to continue enjoying our oil?

Enjoy a 5% discount on your next purchase with this coupon:

Arsenia5

Valid on all our organic products